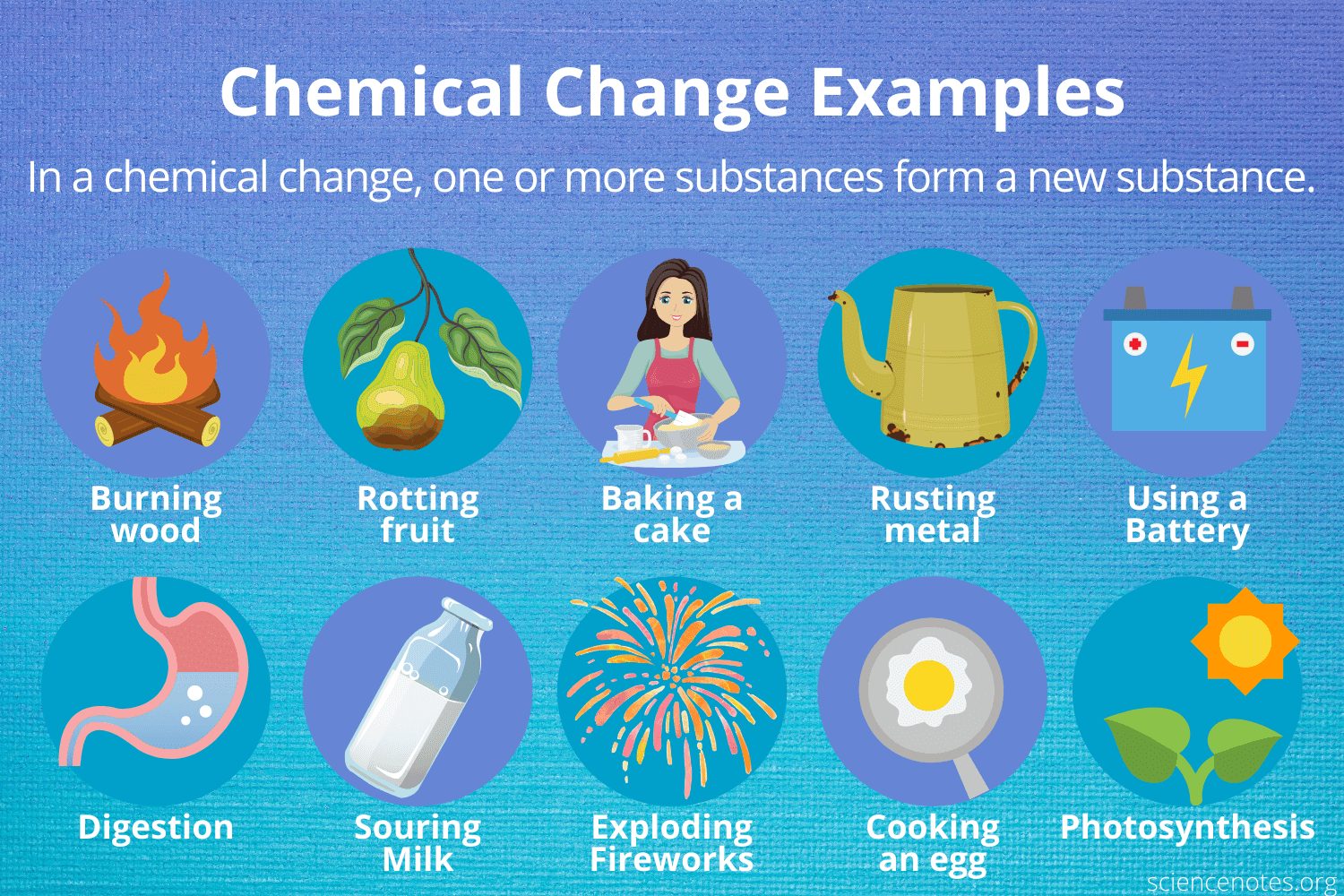

Iron Corroding

When iron is exposed to humid air, it chemically interacts with oxygen and water to generate rust, a reddish-brown powdery material. The following equation describes the rusting process:

Iron (Fe) + Oxygen (O2) (From the air) + Water (H2O) = Rust (Iron oxide, Fe2O3)

Rusting happens in the presence of oxygen and water and the rate of rusting increases with increasing air humidity. Rust progressively consumes or deteriorates the iron, resulting in a significant loss.

Loss due to rusting

Due to the widespread use of iron in the construction of bridges, ships, vehicles, and truck bodies, the economic loss caused by rusting is substantial.

Preventing iron from rusting

By preventing iron from coming into touch with moisture and air, rusting of iron may be avoided. Coating the iron with oil, grease, or paint is the easiest way to get started. Regular application of these coatings is necessary to avoid corrosion.

Zinc or chromium may be applied to the iron to make it better rust-proof. Galvanization is the process of applying a coating of zinc on iron. To avoid corrosion, the iron pipes used to deliver water in our houses are galvanized.

As the body of a ship is constantly in touch with water and the air is also quite humid, rusting is a serious concern in the shipping business. The salt in water accelerates the rusting process. This causes enormous financial losses for the shipping sector. By converting iron into stainless steel, rusting may be avoided. Stainless steel is produced by combining iron with carbon and metals such as chromium, nickel, and manganese. It does not corrode.

Crystallization

The dissolved salts in seawater make it salty. Salt may be extracted from saltwater by evaporation. This method produces impure salt with tiny crystals. It is difficult to discern the crystals' form. By crystallization, it is possible to produce large crystals of pure substances from their solutions. It is an example of a physical transformation.

Definition of Crystallization

Crystallization is the process of obtaining crystals by cooling a heated, highly concentrated solution of a material. The technique of crystallization is used to create crystals of pure solid material from an impure solid substance.

Large deposits of pure copper sulfate may be obtained via crystallization of impure copper sulfate powder.

FAQs:

Q1. What is the process of Rusting and how it takes place?

When iron objects are exposed to air for an extended period of time, they get covered with rust, a brown flaky material. This transformation of iron into rust is known as rusting. Rusting happens only when the iron is consistently exposed to wet air or water.

Q2. Can you explain what exactly are "metallic oxides"?

Metal oxides are crystalline solids containing a metal cation and an oxide anion. They interact with water to generate bases and with acids to form salts.

Q3. What is the meaning of "Metal corrosion"?

Corrosion is the breakdown of a substance due to its contact with its environment, and it may occur at any location or at any time throughout the processing of petroleum and natural gas.